Advantages of Our 6 inch Round Led Driving Lights

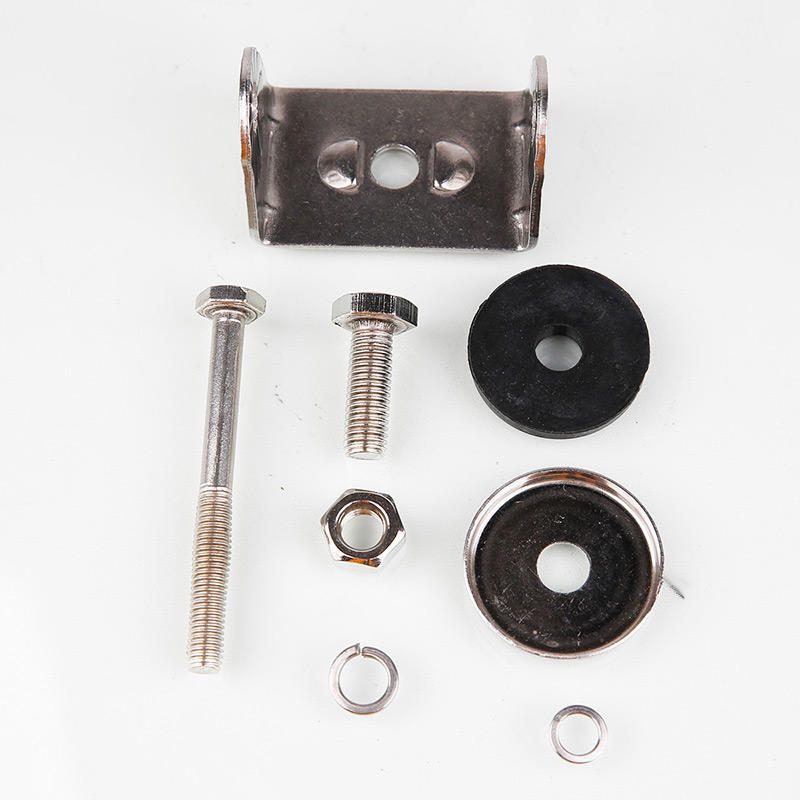

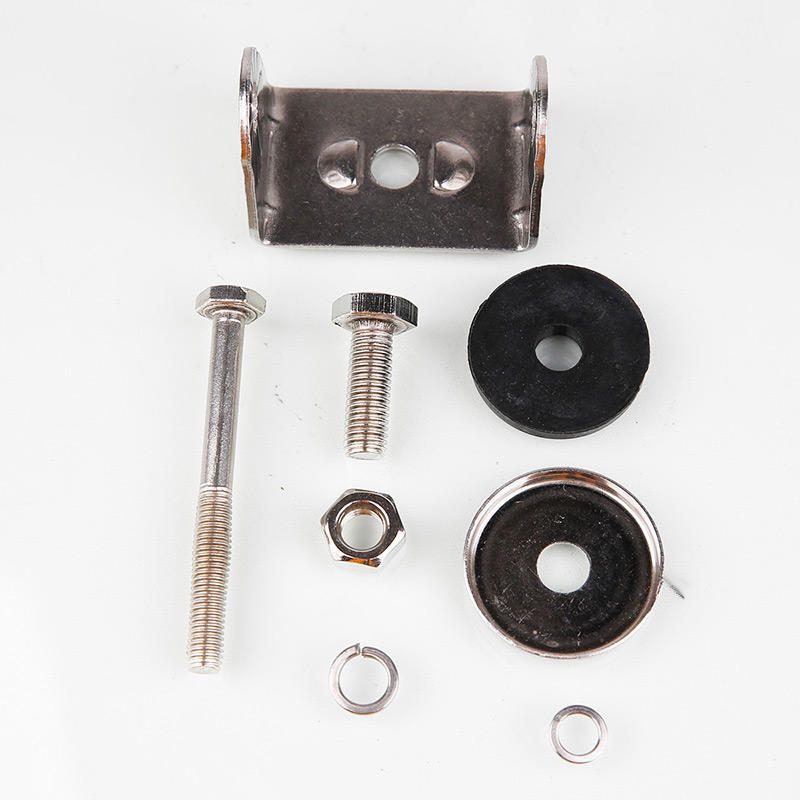

Prevents from corrosion, simple installation with excellent heat dissipation

Super high performance LED lights

Long lifespan, produced under strict test on light form

The performance for heat dissipation is more better than normal halogen bulb

Applications: Garden, Yard, Camping, Boat, Bus, Off-Road Vehicles, ATVs, Trucks, Engineering Vehicles (Excavators, Bulldozers, Road Rollers, Bulldozers, Cranes and Mining Trucks), Special Vehicles (Fire Engineers, Po-lice Cars, Vehicles emergency vehicles, communication vehicles, military command vehicles) Trolleys, trains and tanks.

Specification of 6 inch Round Led Offroad Lights

| Model Number |

MS-2265 |

| Brand |

Morsun |

| Watt |

51W |

| Voltage |

DC 9-32V |

| Lumen |

3740LM |

| Housing Material |

die-cast aluminum |

| Lens Material |

PC |

| Lens Color |

Transparent |

| Reflector color |

Smoke |

| Trim color |

Black/Red |

| Harness Material |

Stainless Steel |

| Waterproof Rate |

IP67 |

More Photos

Morsun Led Headlights are designed to use for aftermarket replacements for Jeep Wrangler and motorcycles, our high quality led headlights make sure your Jeep Wrangler and motorcycles are ready for the road and trails. These led headlights for Jeep Wrangler and motorcycles are built with shatterproof and waterproof IP67 projector lens, they can be used in a variety of environments.

We pride ourselves as one of the leading manufacturers and exporters of high quality led headlights for Jeep Wrangler and motorcycles with reasonable price. With our high quality Jeep Wrangler led headlights our customers are getting a higher quality light output comparing with the original ones. In addition, the unique aluminum housing is designed to be waterproof, anti-corrosion and fast heat dissipation to extend the lifespan of the headlights. Our headlights have 12 months warranty which means we will provide our best service in warranty period so that you never need to worry about using our lights.

Quality Control

- Raw material inspection

- Chip mounting

- Check PCB electrical parameters

- Put heat-conducting silicone grease and PCB into the housing

- 2 hours aging test of the semi-finished product

- Assembled optical component dust removal and cleaning

- Check electrical parameters and optical correction

- Assembling lens by machine

- Lens fixture

- 2 hours aging test and vacuum pumping to solve inside fog problem

- Laser logo

- Packing and shipping

Exhibition