Our 7 inch round

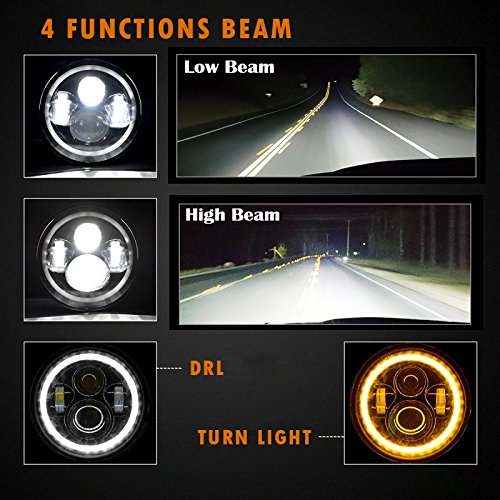

Jeep Wrangler TJ led headlights come with 4 beam modes including high beam, low beam, white halo drl and amber turn signals, 6500K color temperature which close to natural sunlight to improve the clarity of driving view and increase driving comfort. These Jeep TJ halo headlights are DOT complied and Emark approved which is legal on road in North America and Europe. The Jeep TJ led headlights have the characteristics of low consumption, efficient, energy saving, good waterproof and dustproof performance. Fast on/off response time, long service life for more than 50000 hours. Fits for Jeep Wrangler JK TJ LJ CJ.

Specification of Jeep Wrangler TJ led headlights

| Model Number |

MS-881W |

| Brand |

Morsun |

| Car |

Jeep |

| Model |

Wrangler JK, TJ,LJ,CJ |

| Dimension |

7 inch led headlight |

| High Beam |

45W 3620LM |

| Low Beam |

30W 2480LM |

| Halo Color |

Orange drl and amber turn signal |

| Color Temperature |

6500K |

| Housing Material |

Die-cast aluminum housing |

| Housing Color |

Black/Chrome |

| Lens Material |

PC |

| Waterproof Rate |

IP67 |

| Certifications |

DOT, SAE, IP67, CE, RoHS |

| Lifespan |

More than 50,000hrs |

| Warranty |

12 Months |

Application

Product Display

Compatible For

2006 Jeep Wrangler TJ

2005 Jeep Wrangler TJ

2004 Jeep Wrangler TJ

2003 Jeep Wrangler TJ

2002 Jeep Wrangler TJ

2001 Jeep Wrangler TJ

2000 Jeep Wrangler TJ

2006 Jeep Wrangler TJ

1999 Jeep Wrangler TJ

1998 Jeep Wrangler TJ

1997 Jeep Wrangler TJ

Advantages of Our Auto Lighting Systems

- Projector Lens High Low Beam

High-definition optical material, strong penetration, spotlight

- High Brightness

Brightness is 3 times of the halogen lamps

- Light Sensitivity

Light is softer to prevent from glare

- High Energy Saving

Reduced energy consumption by at least 50% (low energy consumption means low fuel consumption)

- Long Lifespan

High quality LED chips have a long lifespan which is more than 50,000 hours

- Waterproof

Highly sealed connector, waterproof rate IP67, anti-corrosion, protect the headlights from bad various environments

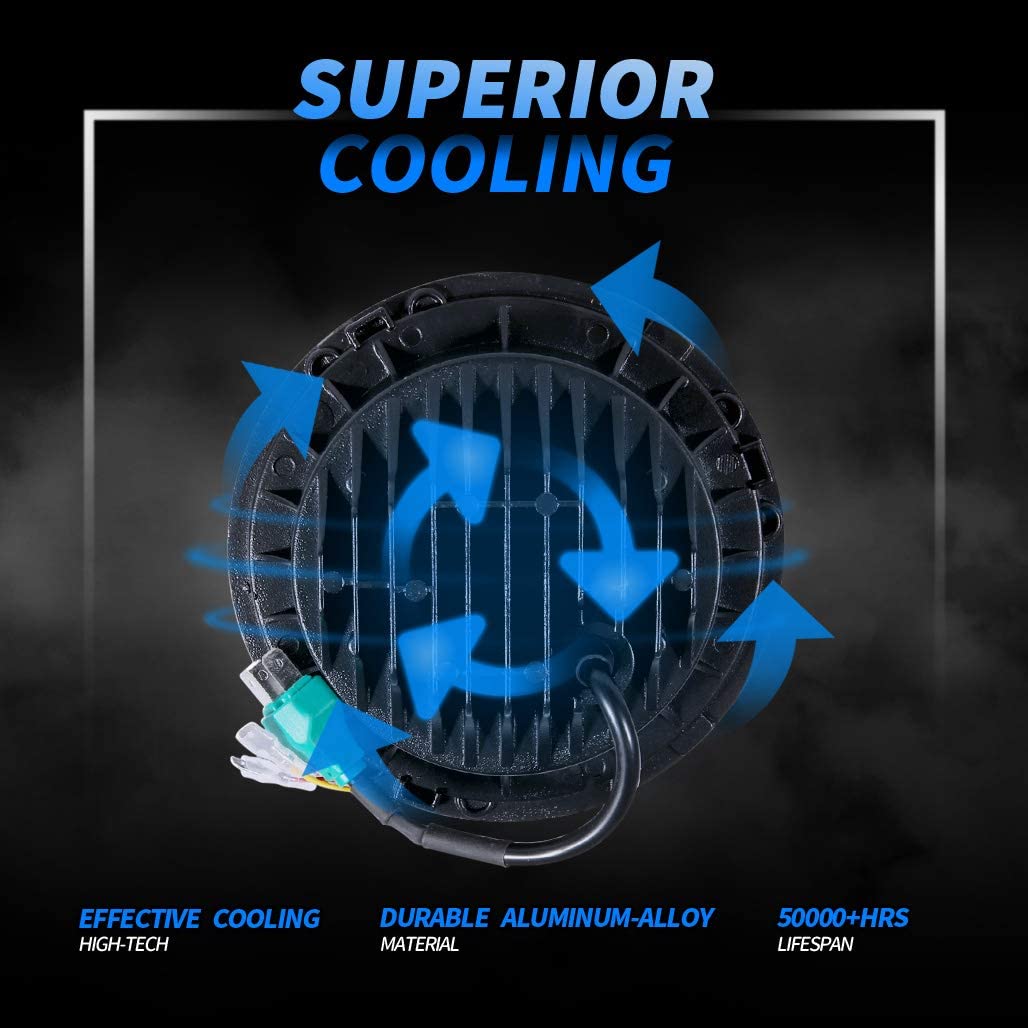

- Die-cast Housing

Aluminum housing, corrosion resistant, fast heat dissipation to extended lamp lifespan

- Easy to install

Plug and play, easy to install, does not damage the original car electrical system

Morsun Led Headlights are designed to use for aftermarket replacements for Jeep Wrangler and motorcycles, our high quality led headlights make sure your Jeep Wrangler and motorcycles are ready for the road and trails. These led headlights for Jeep Wrangler and motorcycles are built with shatterproof and waterproof IP67 projector lens, they can be used in a variety of environments.

We pride ourselves as one of the leading manufacturers and exporters of high quality led headlights for Jeep Wrangler and motorcycles with reasonable price. With our high quality

Jeep Wrangler led headlights our customers are getting a higher quality light output comparing with the original ones. In addition, the unique aluminum housing is designed to be waterproof, anti-corrosion and fast heat dissipation to extend the lifespan of the headlights. Our headlights have 12 months warranty which means we will provide our best service in warranty period so that you never need to worry about using our lights.

Quality Control

- Raw material inspection

- Chip mounting

- Check PCB electrical parameters

- Put heat-conducting silicone grease and PCB into the housing

- 2 hours aging test of the semi-finished product

- Assembled optical component dust removal and cleaning

- Check electrical parameters and optical correction

- Assembling lens by machine

- Lens fixture

- 2 hours aging test and vacuum pumping to solve inside fog problem

- Laser logo

- Packing and shipping

Exhibition