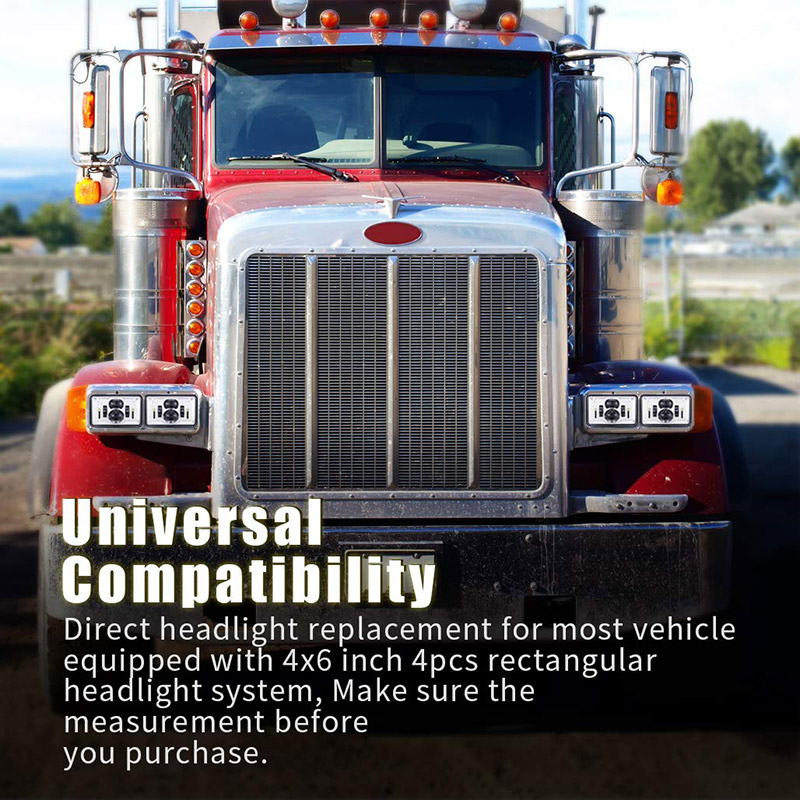

This rectangular 1986-2007

Peterbilt 379 led headlights come with 6500K color temperature which closes to natural sunlight to improve the clarity of driving view and nncrease driving comfort. Well waterproof and dustproof performance. Durable housing case with good performance heat sink. High energy density and light intensity to expand the line of vision, increase safe driving conditions for you. Our led headlights for 2007 Peterbilt 379 378 357 on-highway (Class 8) have Low consumption, efficient, energy saving and environmental protection characteristics. High power on/off response time, long service life for more than 50000 hours. Plug and play, easy installation, usually costs you around 15 minutes for installing. Fits for 1986-2007 Peterbilt 379 378 357 etc which with 4x6 inch headlights.

Specification of 4x6 Peterbilt 379 Led Headlight

| Model Number |

MS-4686 |

| Brand |

Morsun |

| Car |

Truck |

| Model |

Peterbilt |

| Dimension |

4x6 square led headlight |

| High Beam |

55W 3500LM |

| Low Beam |

30W 2800LM |

| Halo Ring |

No |

| Color Temperature |

6500K |

| Housing Material |

Die-cast aluminum housing |

| Housing Color |

Black/Chrome |

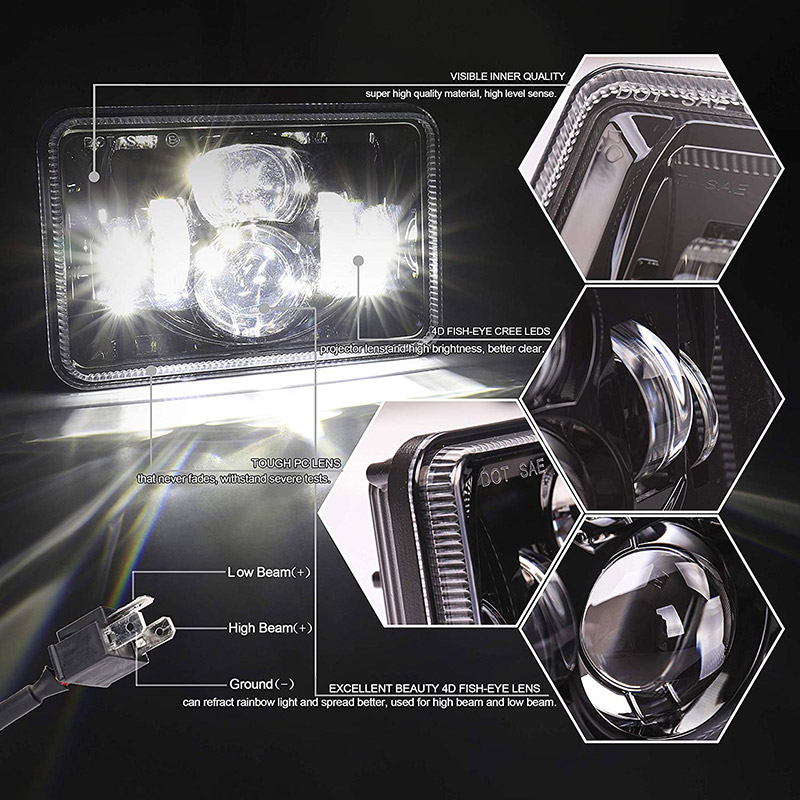

| Lens Material |

PC |

| Waterproof Rate |

IP67 |

| Certifications |

IP67, CE, RoHS, DOT, SAE |

| Lifespan |

More than 50,000hrs |

| Warranty |

12 Months |

Product Images

Fitment

1978 - 1983 American Motors Concord

1980 - 1988 American Motors Eagle

1979 - 1983 American Motors Spirit

1975 - 1990 Buick Electra

1976 - 1986 Buick LeSabre

1982 - 1987 Buick Regal

1975 - 1985 Buick Riviera

1975 - 1985 Cadillac Eldorado

1975 - 1985 Cadillac Seville

1982 - 1992 Chevrolet Camaro

1982 - 1987 Chevrolet Cavalier

1982 - 1987 Chevrolet El Camino

1980 - 1988 Chevrolet Monte Carlo

1979 - 1986 Ford Mustang

1993 - 1997 Ford Probe

1982 - 1992 Chevy Camaro Iroc-Z

1976 - 1987 Pontiac Grand Prix

1987 Chevy Silverado V10

Freightliner FLD120 112 FLD

Peterbilt 379 378 357

Kenworth T400 T600 T800 W900B W900L Classic 120/132 HK Classic

Features of 4x6 LED Headlight for Trucks

- Easy to plug and play.

- Energy-Saving. More bright light out, less power in.

- 100% die-cast Aluminum housing is good to Dissipate heat.

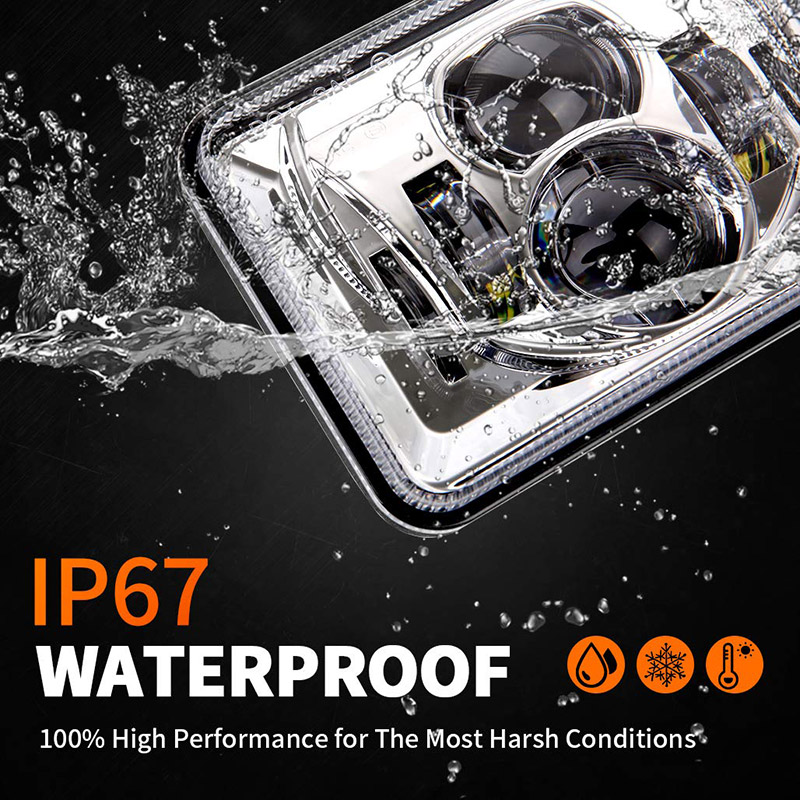

- IP67, better waterproof, dispelling fog inside from breather film.

- we are more specialize in design & manufacture of vehicle lighting solution.

Advantages of 4x6 Truck Led Headlights

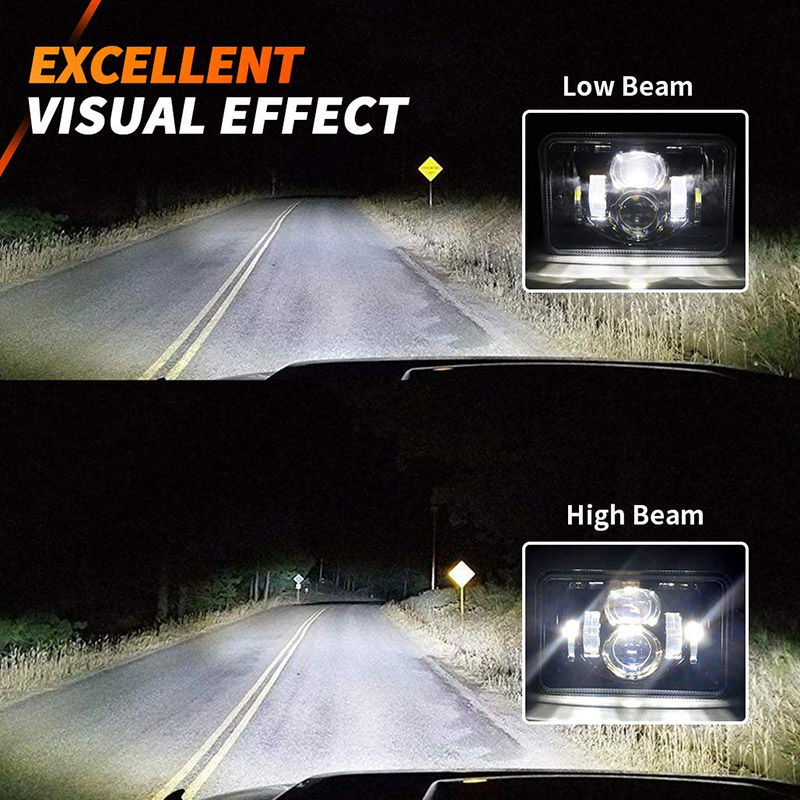

- Projector Lens High Low Beam

High-definition optical material, strong penetration, spotlight

- High Brightness

Brightness is 3 times of the halogen lamps

- Light Sensitivity

Light is softer to prevent from glare

- High Energy Saving

Reduced energy consumption by at least 50% (low energy consumption means low fuel consumption)

- Long Lifespan

High quality LED chips have a long lifespan which is more than 50,000 hours

- Waterproof

Highly sealed connector, waterproof rate IP67, anti-corrosion, protect the headlights from bad various environments

- Die-cast Housing

Aluminum housing, corrosion resistant, fast heat dissipation to extended lamp lifespan

- Easy to install

Plug and play, easy to install, does not damage the original car electrical system

Morsun Led Headlights are designed to use for aftermarket replacements for Jeep Wrangler, our high quality led headlights make sure your Jeep Wrangler is ready for the road and trails. These led headlights for Jeep Wrangler are built with shatterproof and waterproof IP67 projector lens, they can be used in a variety of environments.

We pride ourselves as one of the leading manufacturers and exporters of high quality led headlights for Jeep Wrangler with reasonable price. With our high quality

Jeep Wrangler led headlights our customers are getting a higher quality light output comparing with the original ones. In addition, the unique aluminum housing is designed to be waterproof, anti-corrosion and fast heat dissipation to extend the lifespan of the headlights. Our headlights have 12 months warranty which means we will provide our best service in warranty period so that you never need to worry about using our lights.

Quality Control

- Raw material inspection

- Chip mounting

- Check PCB electrical parameters

- Put heat-conducting silicone grease and PCB into the housing

- 2 hours aging test of the semi-finished product

- Assembled optical component dust removal and cleaning

- Check electrical parameters and optical correction

- Assembling lens by machine

- Lens fixture

- 2 hours aging test and vacuum pumping to solve inside fog problem

- Laser logo

- Packing and shipping

Exhibition